Production of welded

of parts and structures

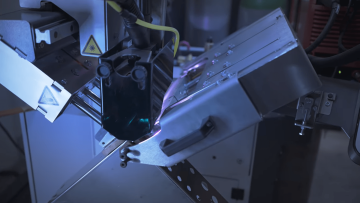

We specialize in welding aluminum and stainless steel fabrication in top quality. We are certified production for rail transport, military, building structures. We also manufacture stainless steel baby slides, switch cabinets, pressure piping and tanks.

During the production process, we take the utmost care from the design phase to the final product. We therefore use the most modern machinery and software.

OUR TECHNOLOGIES

Welding is the alpha and omega of our work. We can supply you with welded parts and complete products in aluminium and stainless steel.Read in detail what we can do.

OUR ACTIVITIES

Our products guarantee the highest quality, whether in the field of military technology, rolling stock, construction or general mechanical engineering.

QUALITY POLICY

What are our production possibilities?

In our production facilities of about 700 m2 we have 3 workplaces for manual arc and laser welding, 1 workplace for automated welding, workplace for CNC technology, surface treatment and assembly. We work with light and medium weight products up to 200 kg weight/piece.

Our

references