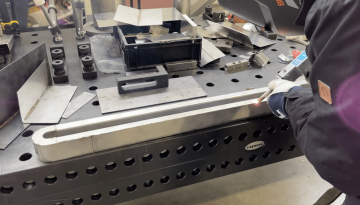

Take a look at our workshop

The welding process requires a professional approach from beginning to end. Our elaborate quality policy pertains to every individual area of our production.

Welding

All the parts we produce are welded and welding is thereby our basic production technology, which is of the highest importance to us. Welding methods and their mechanisation are widespread in our company. We can offer very productive welding methods and thus guarantee repeatable quality and the required capacity for a relatively reasonable price.

- Manual welding

- Manual laser welding

- Orbital welding

- Rotary welding

- Longitudinal welding

- Resistance welding

- Stud welding

CNC machining

HAAS VF-3SSYT

The vertical machining centre offers high spindle rotation speeds of up to 12k RPM, rapid traverse in 3 axes and fast tool change (30+1 magazine), which are necessary for high-volume production and reduced cycle times.

-

Work travel in X, Y, Z: 1,016x660x635 mm

-

Working table dimensions: 1,372x610 mm

We primarily use SolidWorks CAM Professional software to program the CNC process so that it is always efficient.

NC round bending

Prinzing RBB 85/103 Four Roll Round Bending Machine

On the RBB bending machine, not only pipes but also other cross-sectional shapes can be produced productively due to the NC control.

-

Metal sheet working width: 1,030 mm

-

Sheet thickness: 2.5 mm (400 N/mm2)

-

Upper cylinder diameter: 85 mm

-

Working speed: 0-14 m/min

AMOB MAH 40/3 CNC Profile Bending Machine

We normally bend stainless steel pipes and rods on this machine, which then form part of the children’s slides and children’s playgrounds.

Surface treatment

Ballotini blasting

We use ballotini B112 (150-250 µm) or B159 (80-150 µm).

We have a 4x4 m blast box with a Normfinish LP2500 blast system, which is intended more for medium sized parts (3 to 50 kg). We mainly blast stainless steel weldments from our production, such as children’s slides, parts for rolling stock, etc.

Coupling components

Riveting and pressing

We primarily use fasteners from KVT – Fastening and Böllhoff manufacturers.

Pressing elements are installed with PEMSERTER® Series 4®, riveting elements with a Böllhoff RIVKLE P2007 gun.

3D design

SolidWorks

For the creation of 3D designs and production documentation, we use the SolidWorks design software and its add-ons such as CAM PROFESSIONAL for machining and SIMULATIONS for static calculations.

If the customer provides us with documentation, it helps us in pricing the final product.

When a customer has an idea of a product (e.g. a water tank) and does not have production documentation (laser machine, press brake or machine tool data), we can create customised 3D and production data.