Manual welding

The equipment in our welding workshop is very diverse. Our experienced and certified welders work with the best equipment that can be found on the market. Basically, this primarily comprises Fronius welding equipment for MIG, MAG, TIG and laser welding methods, the use of higher welding mechanisation such as a rotary positioner, Push Pull welding torches as well as Siegmund clamping and preparation welding tables.

4x MagicWave 3000 Comfort Job

1x FDV 22 truck

2x MagicWave 3000 Comfort Job

1x RWT POTTER 425.91 Welding positioner

1x TPS 320i Pulse incl. Push Pull torch

1x TPS 270i Pulse

1x TS 4000 Pulse

Manual laser welding

This is a state-of-the-art technology that enables us to productively weld stainless-steel parts of the highest quality with minimal input heat. It is especially suitable for longer welds on stainless-steel weldments with a thickness of up to 4.0 mm.

KSK ROTARY AUTOMATIC MACHINE

Fitted with an EWM power supply for welding mainly pressure vessels (including aluminium) and various rotary weldments.

Orbital welding

ORBITEC EVO 200 WP

We offer orbital welding, especially of stainless steel pipe assemblies.

Longitudinal welding

Longitudinal corner welding

CORNER WELD 320 welding equipment from the German manufacturer Schnelldorfer for automated longitudinal welding of corners of small switchboards and boxes. The equipment mainly excels for its high-quality welds without need for additional grinding, for its repeatability and production capacity. The welding machine is intended for welding corners up to 320 mm in length.

We offer free capacities of this equipment. In the case of specific materials and box shapes, we can retrofit the machine for the particular project with, for example, an aluminium welding power supply and cold wire feeding.

Longitudinal pipe welding

BOKI ZEPPIN 1000 – We offer free capacities of this equipment. In the case of specific materials and box shapes, we can retrofit the machine for the particular project with, for example, an aluminium welding power supply and cold wire feeding.

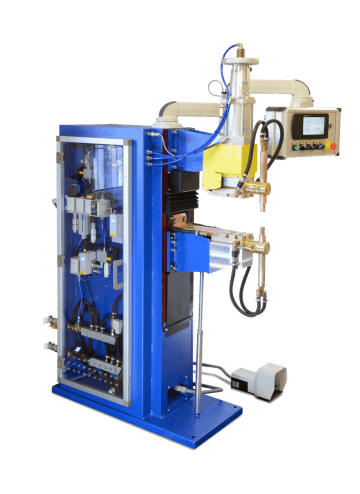

Resistance welding

Stationary machines with a power of up to 125 kVA for sheet metal and nut welding

Tecna 4644

Spot welding machine with a power of 25 kVA (duty factor 50%) for welding thin sheets up to 2+2 mm thick

RW Tech Serie4

The medium frequency spot-welding press RW Tech Serie4 with an output of up to 127 kVA (duty factor 50%) is primarily intended for welding nuts in our production. In any case, its performance makes it possible to even weld aluminium sheets up to a thickness of 4+4 mm.

Stud

welding

Highly productive workplace PRO-C 1000 for stud welding equipped with PRO-SPLIT adapter for connection of up to 4 welding guns.

Microprocessor controlled welding unit PRO-C 1000 using the spike ignition method. As studs we most often use M3 to M10 bolts or posts with an internal thread. Welded materials are steel, stainless steel and aluminium. This unit is additionally equipped with a special PRO-SPLIT adapter, which allows the connection of up to 4 welding guns to one welding power supply. In this way we can productively and very precisely weld several types of studs within one clamping of the part in the fixture.

We weld with precision,

that exceeds expectations

Looking for professional welding services you can rely on? We will ensure maximum efficiency and quality for your project. See for yourself and visit our online form for more information and individual consultation.