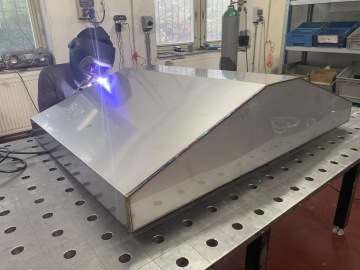

From design to production

We work in Solidworks 3D design system. We prepare customer documentation and fine-tune the details so that the result is perfect. Where we lack machines, we have reliable suppliers. At the end of the production process there must always be a quality product and customer satisfaction.

Containers

and tanks

We manufacture non-pressure and pressure tanks up to 2 m3.

We manufacture pressure parts requiring PED based on the customer’s technical design. A typical implementation is a twin-shell vessel, containers, water tanks, aluminium tanks for caravans, etc.

Pressure tanks and pipelines

They require absolute precision and consistent quality control already during production. We are operating according to ISO 3834-2 certification and related regulations, which ensure the maximum weld quality and the overall corresponding quality of the final product.

Stainless steel slides and play elements

Welding of playground equipment, such as slides or various structures for swings and climbing frames, must be absolutely precise and of high quality. The same applies to sporting elements.

That is why we approach the design preparation phase with ultimate care, where we plan the details of the joints, the welding process and method, the material used, preparations, etc. The result must always be a perfect and dimensionally accurate product.

Light-weight structures

We manufacture light-weight statically stressed metal structures, such as parts of balconies, advertising stands, scaffolding or supporting parts of lighting, as customised production. In the case of dynamically stressed constructions, these are primarily wheel frames or vehicle components. The basic material is mainly aluminium, exceptionally also stainless steel. For building components, welded parts are made according to EN 1090 up to EXC3.

Atypical implementation

We can implement various atypical projects according to the customer’s request and specific requirements. It is not a problem for us to produce furniture, sanitary equipment or, for example, 3D stainless steel signs.

Every product is important

Welding is our mission and we treat every product as if it is the only one we will ever make.